A chemical company in Silvassa faced serious operational issues due to water with extremely high Total Dissolved Solids (TDS). The excessive scaling in pipelines restricted water flow, increased maintenance needs, and drove up water treatment costs.

Background

High TDS levels cause heavy scaling in industrial water systems, requiring frequent maintenance and expensive treatments. The company needed a cost-effective and sustainable solution to resolve these issues while maintaining smooth operations.

Challenges

🔹 Severe pipeline scaling due to high TDS

🔹 Reduced water flow, affecting operations

🔹 High treatment costs from using RO and softeners

To tackle these problems, the company partnered with Eximious, known for its innovative and simple water treatment solutions.

Solution

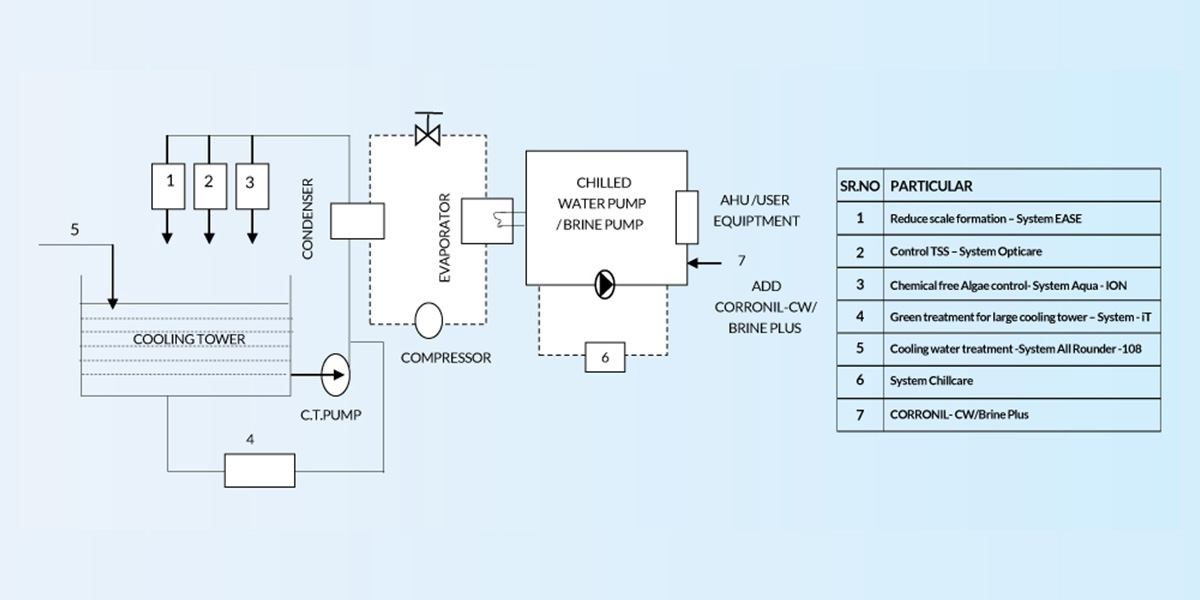

Eximious implemented a two-step approach:

- System Cleaning & Descaling: Using D’Scale 1000, D’Scale 3000, and the System 2nFz forward-reverse descaling machine, Eximious thoroughly cleaned and descaled the pipelines.

- Installation of System EASE: This advanced system was installed to remove excess salts from the water, preventing future scaling.

Results

- Improved Water Flow – Scaling issues were eliminated, restoring smooth water flow.

- Lower Maintenance Costs – The system remained clean, reducing frequent maintenance.

- Reduced Water Treatment Costs – Less dependency on expensive RO and softeners.

Conclusion

With Eximious’ innovative solutions, the company eliminated scaling problems, reduced costs, and enhanced overall operational efficiency.

Contact us to learn how Eximious can help optimize your water treatment processes.