TF System Audit, Design Consultancy

Description:

While starting a new project or expanding existing activity, it's critical to ensure existing thermic fluid system can meet increased heat and flow demands. Failing to do so can result in temperature inconsistencies, safety risks, and operational challenges at later stage.

Benchmark your existing thermic fluid system with latest norms. Assess its current performance to determine if it can deliver adequate heat and flow. Additionally, identify any safety, operational, and maintenance issues.

A thermic fluid system audit ensures your system operates efficiently and safely.

Key Features

- Industry experts with over 35 years of experience per consultant.

- Recognized reviewers of research papers for the international journal Elsevier.

- Hold three approved patents, with two additional patents under review.

- In-depth knowledge of various production processes across diverse industries.

Benefits of a Walk-Through Thermic Fluid Audit

- Current System Assessment: Benchmark your system against safety, operational, maintenance, and design standards.

- Improvement Opportunities: Identify areas for performance enhancements.

- Strength and Weakness Analysis: Pinpoint robust and vulnerable aspects of your system.

- System Health Check: Evaluate overall system condition and address deficiencies.

- Root Cause Diagnosis: Identify underlying issues and receive actionable recommendations.

- Extended Fluid Lifecycle: Enhance thermic fluid longevity, minimizing shutdowns and downtime.

- Enhanced Understanding: Gain deeper insights into your thermic fluid system and its operation.

Thermic Fluid System Design Consultancy:

Ensure your system is correctly designed from the outset to avoid future operational challenges. Many issues stem from improper initial designs. Our consultancy services focus on creating well-structured systems tailored to meet your specific needs.

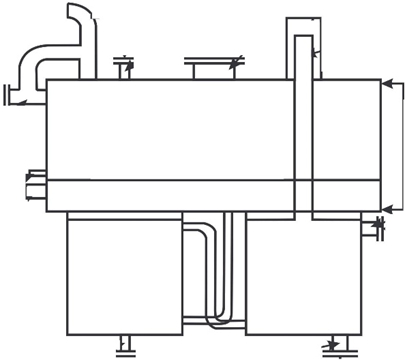

Design of Expansion and Deaeration Tank

A properly designed expansion tank can reduce thermic fluid degradation by up to 60%. The tank's design should not solely depend on heater capacity but must consider the system's total volume and the unique characteristics of the thermic fluid.

Key factors include:

- Type of thermic fluid used.

- Operating temperature.

- Total system volume.

- Correct tank design ensures the optimal performance and longevity of your thermic fluid system.

Case Studies

Optimizing booster Pump Selection in Flexible Packaging

In the flexible packaging industry, a manufacturer specializing in snack packaging films faced a critical decision regarding their pumping system. The team considered removing an existing booster pump to minimize maintenance requirements.

Optimizing Heat Utilization in a Textile Plant Expansion

A leading textile company planned to expand its existing plant, which already had two heaters. Although the heater efficiency was measured by the manufacturer, there was a noticeable gap between heat generation and utilization.