A petrochemical company sought to integrate ETP-treated water into its cooling towers. However, managing TDS levels was a major challenge, as excess TDS led to frequent blowdown, increasing water wastage. The company needed a solution to conserve water while keeping all key water quality parameters within safe limits.

To address this, the company partnered with Eximious, known for its chemico-mechanical solutions for water treatment.

Solution

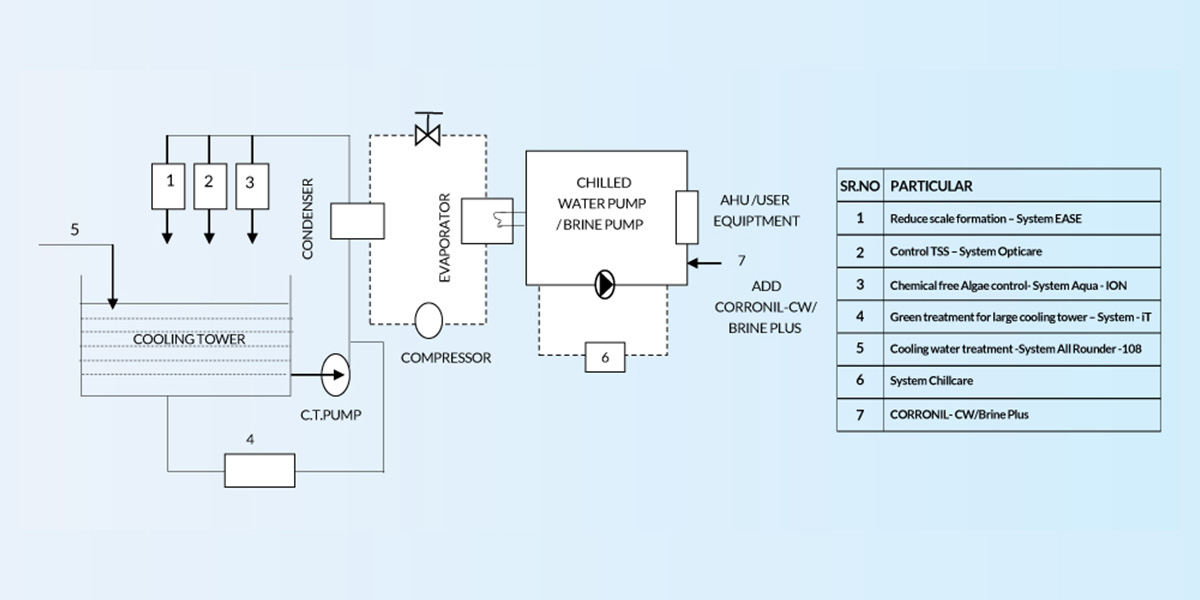

TDS Control with System EASE

Eximious installed System EASE, an advanced system that removes salts in solid form, effectively managing TDS while considering the cooling tower’s total water volume and flow rate.

Microbial Control with SYSTEM iT

To reduce microbial growth, SYSTEM iT was installed, significantly lowering microbial load. This allowed for reduced chemical dosing, optimizing operational costs.

Corrosion Control with ALLROUNDER 108

To protect the cooling system from corrosion, ALLROUNDER 108 was applied—an all-in-one treatment chemical that minimized corrosion without requiring additional treatments.

Results

- Optimized TDS levels – Reduced blowdown and water wastage

- Lower microbial growth – Improved water quality with reduced chemical usage

- Corrosion prevention – Enhanced system lifespan and efficiency

By implementing Eximious’ chemico-mechanical solutions, the company successfully conserved water, reduced chemical use, and improved cooling system performance.

Contact us to learn how Eximious can help optimize your water treatment process and reduce blowdown.