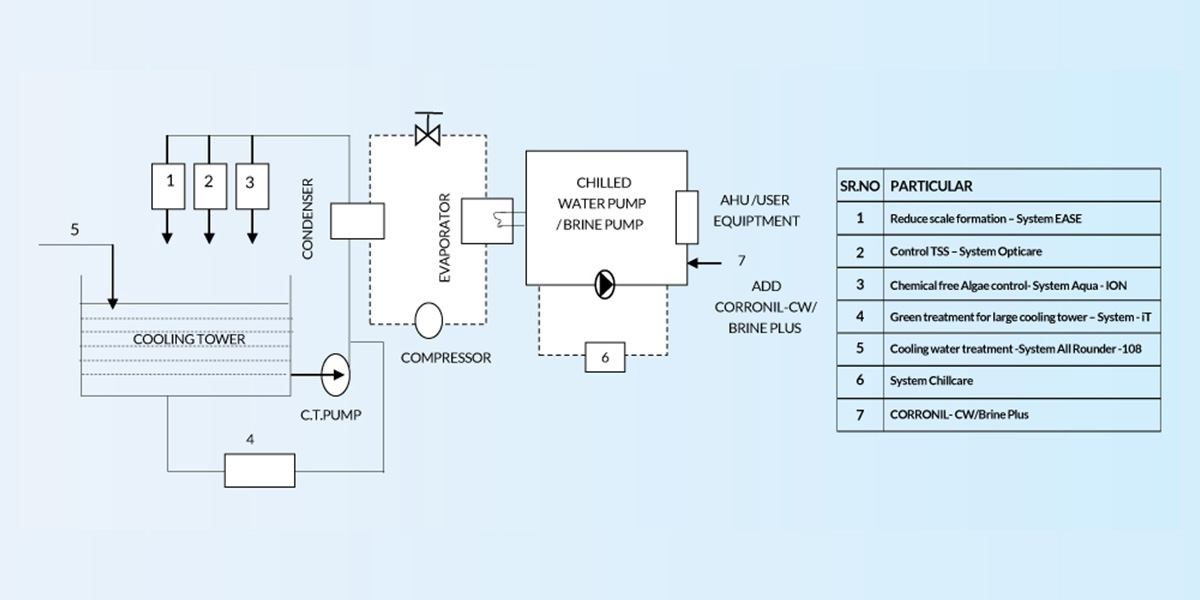

Reducing chemical treatment for Microbial Contamination in the chemical Industry – System Aqua ION

In the chemical industry, the cooling tower was exposed to heavy sunlight, which increased the potential for microbial growth. This posed a persistent challenge. The alternate chemical dose was heavy and costly. The company approached Eximious known for simple and innovative way for a solution that would not involve chemical treatments.