Chemical free, reduced blowdown, water saving cooling water treatment

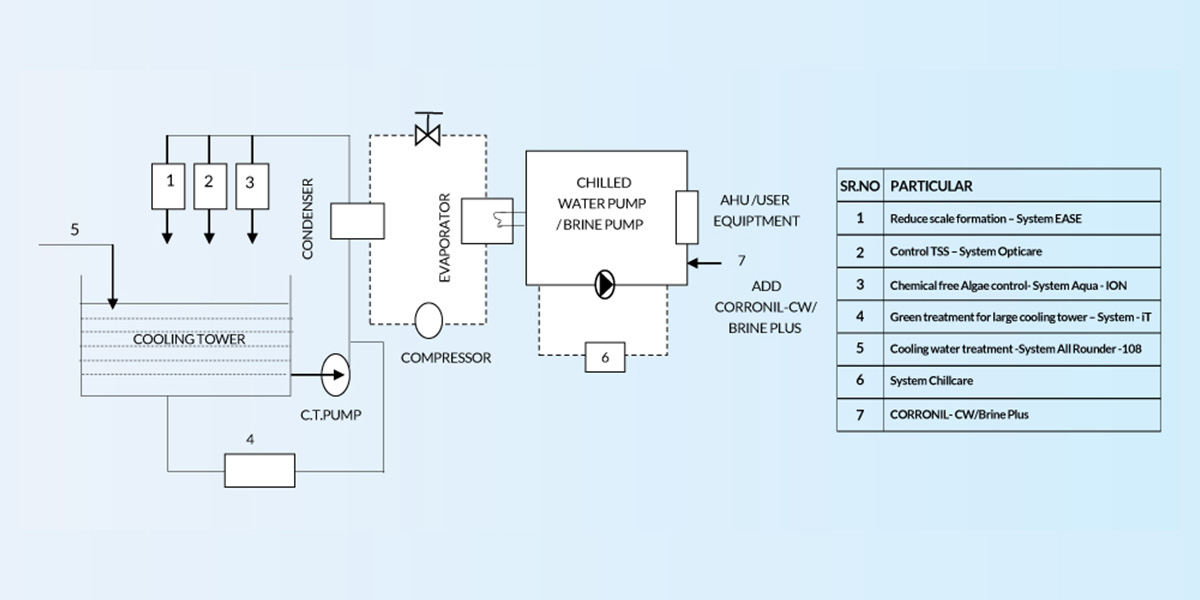

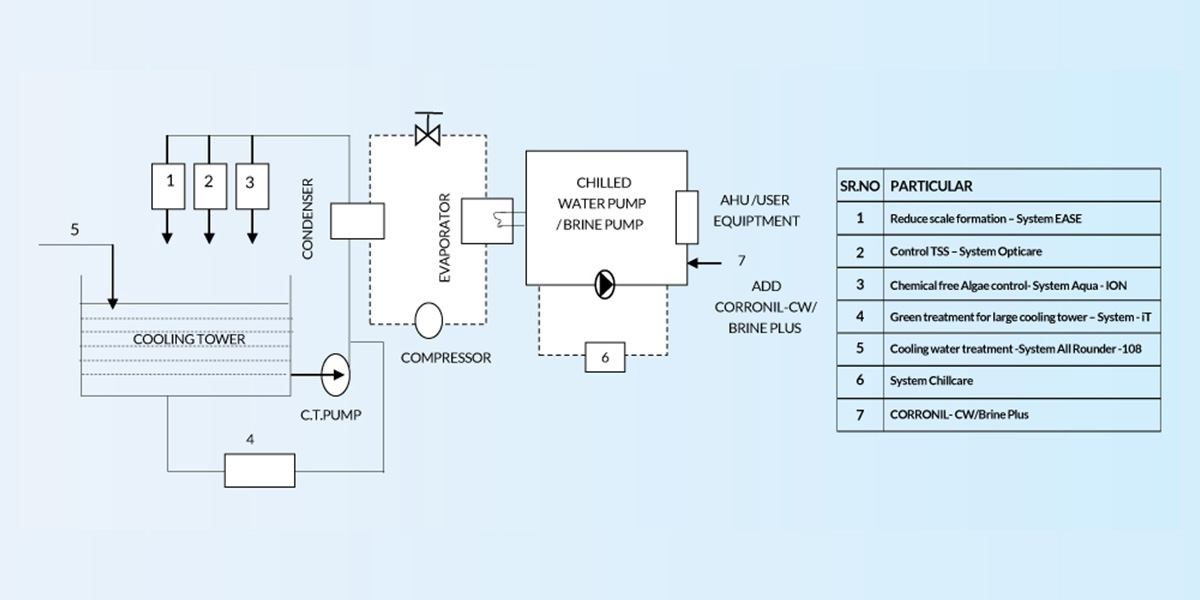

Cooling towers play a critical role in industrial cooling processes, but without effective management of water quality, scaling and corrosion can severely impact water quality affecting performance and increase maintenance costs. Eximious has developed an innovative, almost chemical-free cooling water treatment system that operates through advanced machinery like System Aqua iT, System EASE, System Opticare and Allrounder-108.

Save Water, Reduce Blowdown Cooling Water Treatment Chemico Mechanical Way

A large petrochemical company aimed to reduce its water usage but encountered limited options for improvement in its cooling water treatment processes. The company sought innovative solutions to minimize water usage while maintaining operational efficiency

Cooling Tower Water with ETP for a Petrochemical Company – Use System EASE

A petrochemical company aimed to use treated effluent (ETP) water in its cooling towers but faced problem of controlling Total Dissolved Solids (TDS) to minimize blowdown and water wastage. To ensure efficient water conservation while maintaining safe operating parameters, the company turned to Eximious for its innovative and simple solutions.

Tackling High TDS and Scaling Issues in a Chemical Company – System EASE

A chemical company in Silvassa struggled with severe scaling in pipelines due to water with very high Total Dissolved Solids (TDS). This not only reduced water flow but also made water treatment using reverse osmosis (RO) and softeners costly and inefficient.

Controlling Thermic fluid leak from Valve, Flange and Pump

In thermic fluid systems, leaks from valves, flanges, and pumps not only result in significant oil loss but also pose serious fire and safety hazards. Dr. Thermic Fluid – EXIMIOUS offers advanced solutions to effectively control these leaks and ensure safe, efficient operations.

Hotpack Solution for Thermic Fluid Pump Leakage

Short Description: A packaging company faced persistent leakage from their thermic fluid pump, despite replacing the sleeve, bearings, and verifying alignment. The pump continued to leak approximately 20 drops of thermic fluid per minute In need of a reliable solution, they contacted Dr. Thermic Fluid – EXIMIOUS.

Empowering Sales Teams in Thermic Fluid Products

Introduction A leading lubrication company aimed to launch new products in the thermic fluid line. While they had a strong reputation in the lubricant oil market, their sales team lacked familiarity with the specific terminology ... Read more

Thermic Fluid Training for Enhanced Safety, Operational Efficiency

Introduction A company approached Dr. Thermic Fluid – EXIMIOUS with a thermic fluid report indicating critical parameters. Despite the oil being relatively new, the situation required immediate attention. Eximious explained the process of a naked-eye ... Read more

Enhancing Flash Point in Thermic Fluid Systems

Introduction A multinational company that manufactures inks, resins, and varnishes faced challenges with its multiple thermic fluid systems. These systems had a common expansion tank and separate deaerators, holding a total of approximately 150,000 liters ... Read more

Removing contamination, Improving Flash Point in a Thermic Fluid System

Introduction A major chemical company faced a critical issue with their thermic fluid system when the flash point dropped significantly to 120°C. This decline was traced back to the blending of low-boiling process chemicals, specifically ... Read more

Reducing TAN Value in a Petrochemical Complex Using Thermic Aid SYSTEM AN-O

Introduction A large petrochemical complex faced a significant issue when the Total Acid Number (TAN) of their synthetic specialized-grade imported thermic fluid increased alarmingly from 0.5 to 1.8 within just three months due to external ... Read more

Reducing Total Acid Number (TAN) in Thermic Fluid Systems

Introduction A plywood manufacturer received a thermic fluid sample report indicating a high Total Acid Number (TAN) exceeding 2.5, along with elevated carbon levels. Concerned about the implications of increased acidity—such as pipeline punctures, metal ... Read more